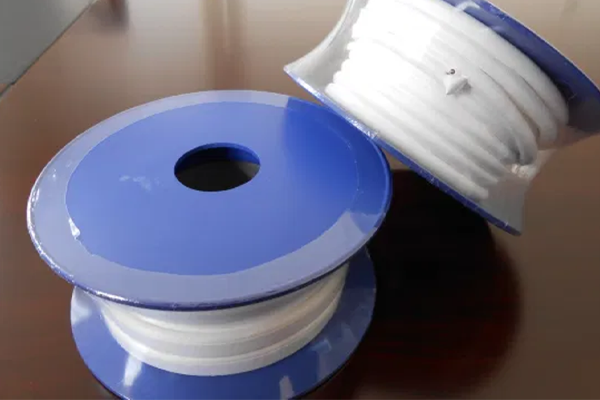

In industrial settings where chemical compatibility, purity, and reliability are essential, pure PTFE gland packing stands out as a gold standard. Unlike conventional packing materials that may deteriorate, contaminate, or react under harsh conditions, pure PTFE is chemically inert, has wide pH tolerance (0–14), resists almost all corrosive media, and can maintain performance across a broad temperature range (typically from –150 °C up to +260 °C in many cases). resources.crconline.com+3GTeek+3SEPCO, Inc.+3 Because it is free of added lubricants or fillers, pure PTFE packing is ideal for applications in pharmaceuticals, chemicals, food processing, and high-purity systems where even minimal contamination is unacceptable. Its low coefficient of friction minimizes wear on shafts and reduces leakage, making it well suited for sealing pumps, valves, mixers, and other rotary or reciprocating equipment

However, achieving optimal sealing with pure PTFE packing requires manufacturing precision, material quality, and accurate installation practices. Dharti Engineering Products is well placed to serve this niche: as PTFE gland packing manufacturers, they can offer braid types, cross-sections, and tolerances customized to your equipment’s stuffing box dimensions, pressure, and speed requirements. Their expertise ensures that the packing fits tightly without cutting or damaging the shaft, accommodates thermal expansion, and delivers consistent sealing performance over long service intervals. In critical systems, such attention to detail reduces downtime, prevents leaks, and safeguards your process integrity.

Frequently Asked Questions (FAQs)

What is pure PTFE gland packing and how is it different from impregnated or composite packings?

Pure PTFE gland packing is made entirely from PTFE fibers, without additional lubricants, fillers, or non-PTFE materials. Impregnated or composite packings may include graphite, aramid, or oil-based lubricants for improved sealing or lower friction—but pure PTFE is more inert and suitable for ultra-clean or corrosive media

What are the typical application ranges (temperature, pressure, speed) for pure PTFE packing?

Pure PTFE packings often operate from –150 °C to +260 °C (depending on grade) and pressure ratings up to ~15 bar for rotary applications (higher for static or reciprocating). Shaft speeds are generally moderate (commonly up to a few meters per second) to avoid frictional heating.

What advantages does pure PTFE packing offer?

-

Excellent chemical & corrosion resistance (pH 0–14) GTeek+3SEPCO, Inc.+3perfectpacking.com+3

-

Very low friction, minimizing shaft wear SEPCO, Inc.+3resources.crconline.com+3perfectpacking.com+3

-

Clean, non-contaminating (no bleed, no filler shedding) GTeek+2perfectpacking.com+2

-

Good performance in many rotating and reciprocating service environments

What are limitations or challenges of pure PTFE packing?

-

Less effective in abrasive media (particles may cause wear)

-

Frictional heating if operated at very high speeds or tight compression

-

May require more careful control of loading stress and shaft alignment

-

Less tolerant of extreme pressure as compared to metallic or graphite-enhanced packings

How should pure PTFE gland packing be installed properly?

-

Use correct cross-sectional size (match stuffing box minus shaft clearance)

-

Cut rings cleanly (90° cuts for rotary, staggered joints)

-

Install rings sequentially and stagger joints

-

Gradually tighten packing to allow sealing compression, without over-compression

-

Monitor during initial run and re-tighten moderately if needed

Why choose Dharti Engineering Products as your pure PTFE gland packing manufacturer?

Dharti offers material expertise, precise manufacturing, customization based on process parameters, and quality assurance tailored for demanding industries. Their focus on custom sizes, tolerances, and consistent purity ensures that your sealing system performs reliably, especially in critical or high-purity applications.