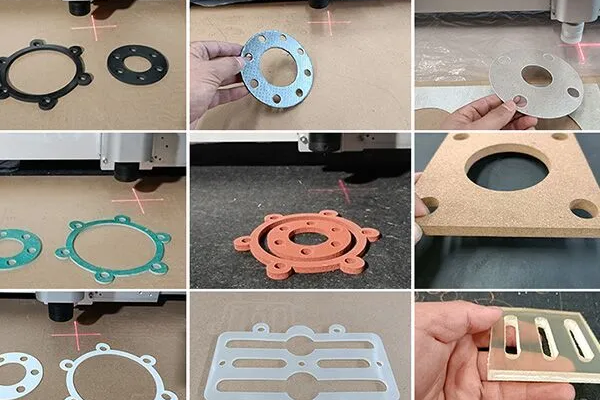

In many industries—be it chemical plants, petrochemicals, power generation, pharmaceuticals, or process engineering—the integrity of piping, flanges, and equipment joints is non-negotiable. That’s where cut gaskets play a crucial role. Cut gaskets are sealing elements manufactured by cutting shapes from sheets of gasket material (rubber, PTFE, compressed non-asbestos materials, etc.) to fit specific flange dimensions, bolt patterns, and operational conditions. Their strength lies in customization: they can match exact dimensions, conform to flange imperfections, and be tailored to handle temperature, pressure, and chemical exposure. Because these gaskets are cut to specification, they ensure tighter seals, reduce leakage risk, and improve system uptime.

Dharti Engineering Products offers a wide range of cut gasket solutions—both asbestos and non-asbestos, PTFE, rubber, grafite, etc. Dharti Engineering Products Their strength lies in precision cutting, material expertise, and the ability to deliver gaskets for special applications. Whether you need a gasket for chemical reactors, steam lines, or specialty equipment with odd flange sizes, Dharti can create cut gaskets that deliver performance and longevity. Their manufacturing capability ensures that even tight tolerances, special bolt hole patterns, or aggressive media compatibility are addressed. With Dharti’s cut gaskets, industries can depend on reliable sealing, fewer maintenance shutdowns, and optimally matched materials for their service environments.

Frequently Asked Questions (FAQs)

What is a cut gasket and how is it different from standard gaskets?

A cut gasket is one that’s custom-cut from a sheet material (rubber, PTFE, compressed fiber, etc.) to the exact shape, size, and bolt pattern needed. Standard gaskets are preformed in common sizes and shapes, so they may not fit special applications.

What materials are commonly used for cut gaskets?

Common materials include rubber (NBR, EPDM, silicone), PTFE, non-asbestos compressed sheets, graphite, and composite materials suited for specific chemical, temperature, and pressure conditions.

How do you choose the right material for a cut gasket?

Selection depends on service fluid (chemistry, corrosivity), temperature, pressure, flange finish, and mechanical stresses. A material must resist degradation, creep, and maintain sealing under operating conditions.

What tolerances and precision are required for cut gaskets?

High precision is necessary for bolt hole alignment, thickness uniformity, and sealing surface contact. Even small deviations can lead to leaks, uneven compression, or gasket failure.

Can cut gaskets be used in high temperature or high pressure systems?

Yes—provided the gasket material is rated for those conditions (e.g. graphite, PTFE, high-grade composites). But for extreme service, design considerations like gasket stress, compression limits, and flange load must be included.

Why choose Dharti Engineering Products for cut gaskets?

Because Dharti offers comprehensive expertise in asbestos & non-asbestos gasket sheets, precision cutting, customization, and material matching for critical industrial services.